如何计算户外灯具的光污染?

随着城市化进程的加快,户外灯具的使用越来越普遍。然而,随之而来的光污染问题也日益严重。光污染不仅影响生态环境,还对人类健康造成负面影响。为了有效管理和减少光污染,了解如何计算户外灯具的光污染是至关重要的。什么是光污染?光污染是指由于人造光源的使用而造成的光环境的不良变化,主要包括以下几种类型:

- 眩光:强烈的光源使人感到不适,影响视力和注意力。

- 光溢出:灯光向周围区域溢出,影响周围的自然环境和夜空观赏。

- 光干扰:人造光源对动物和植物的生理行为产生干扰,如影响动物的觅食、繁殖和迁徙。

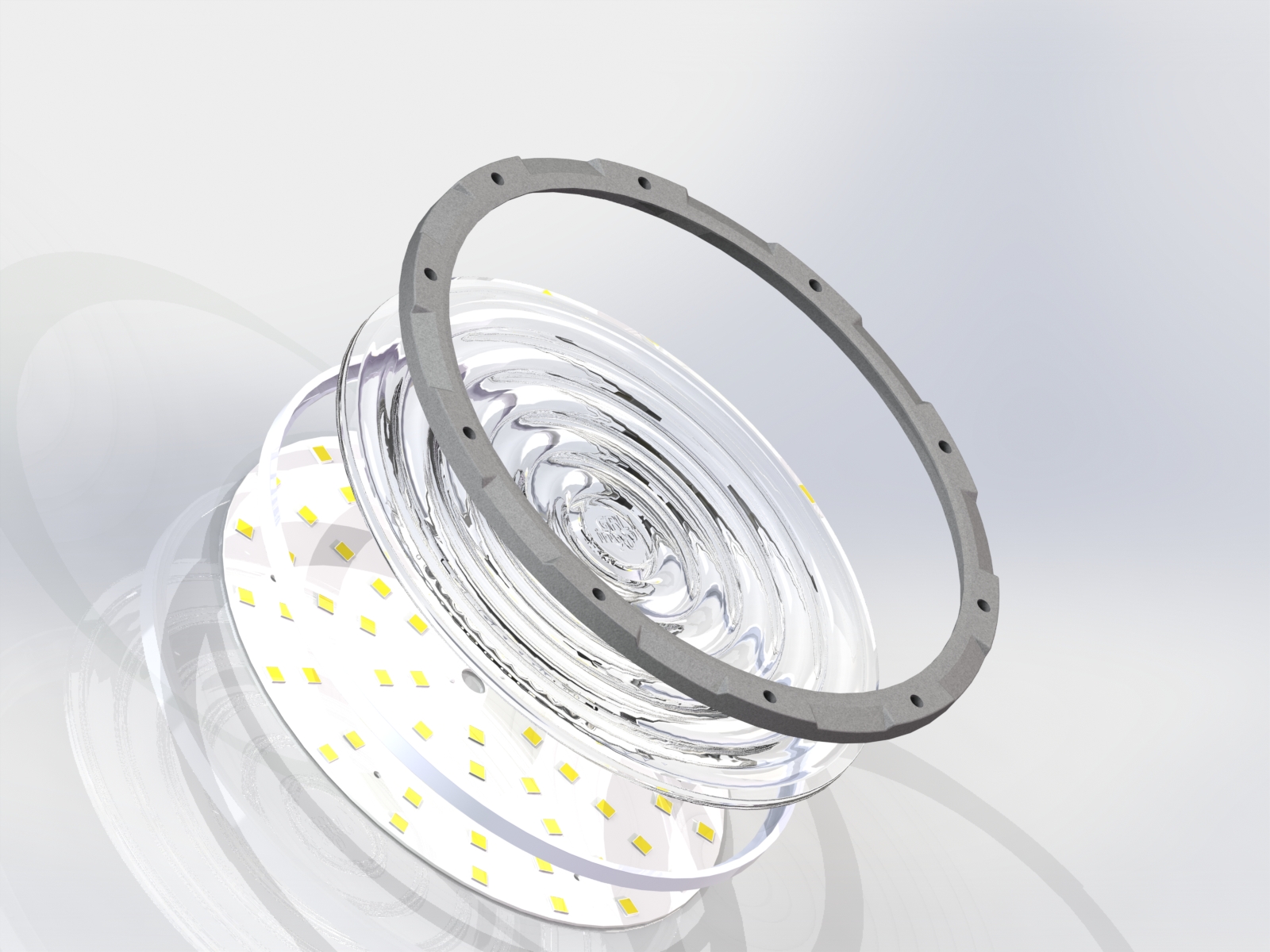

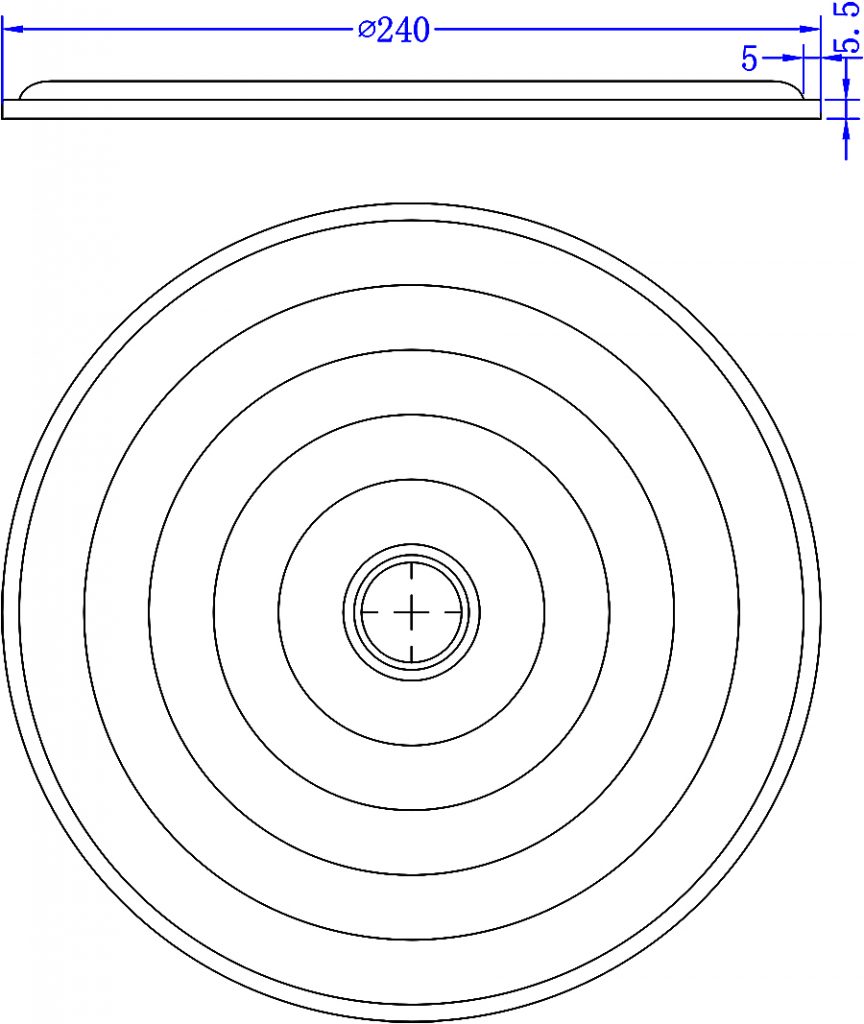

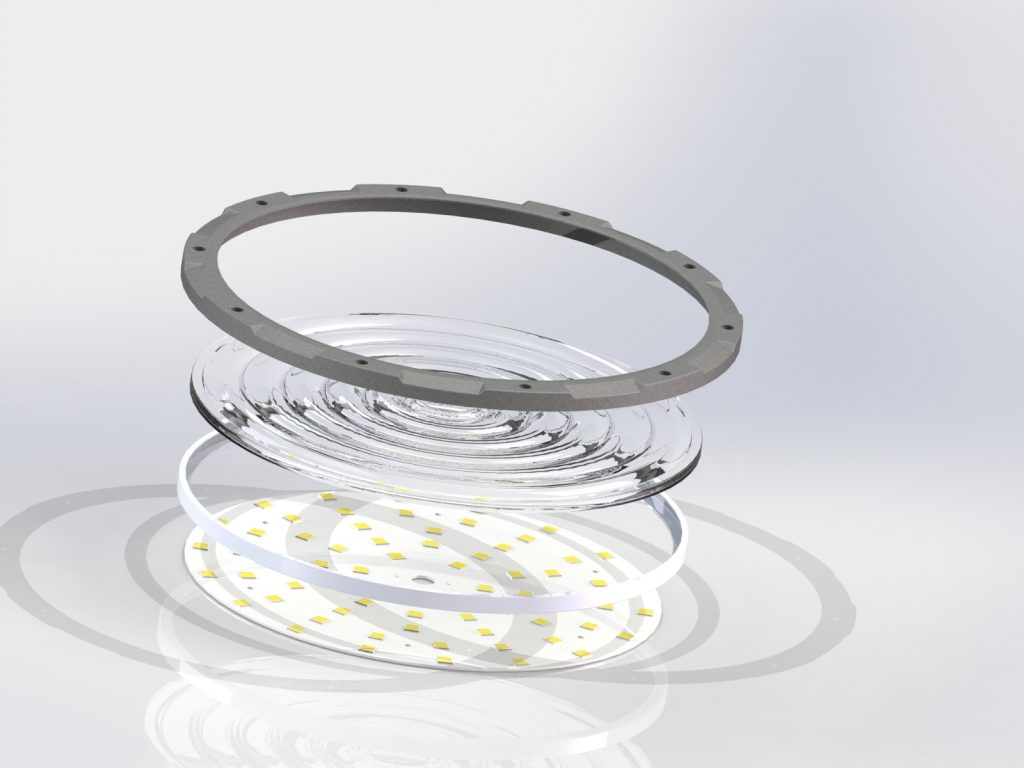

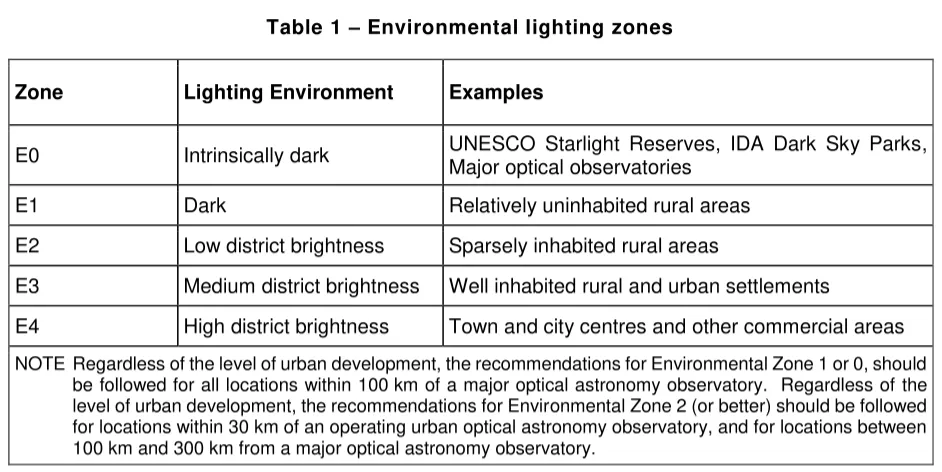

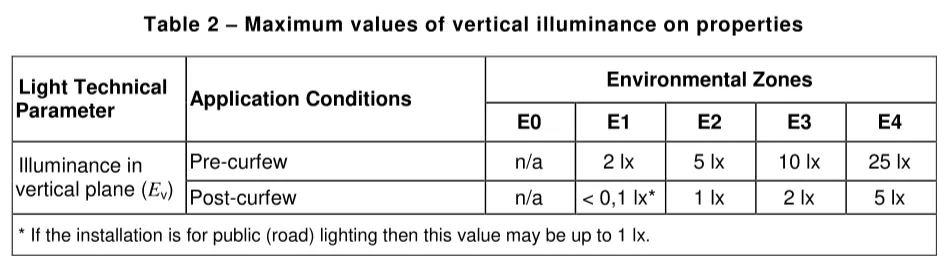

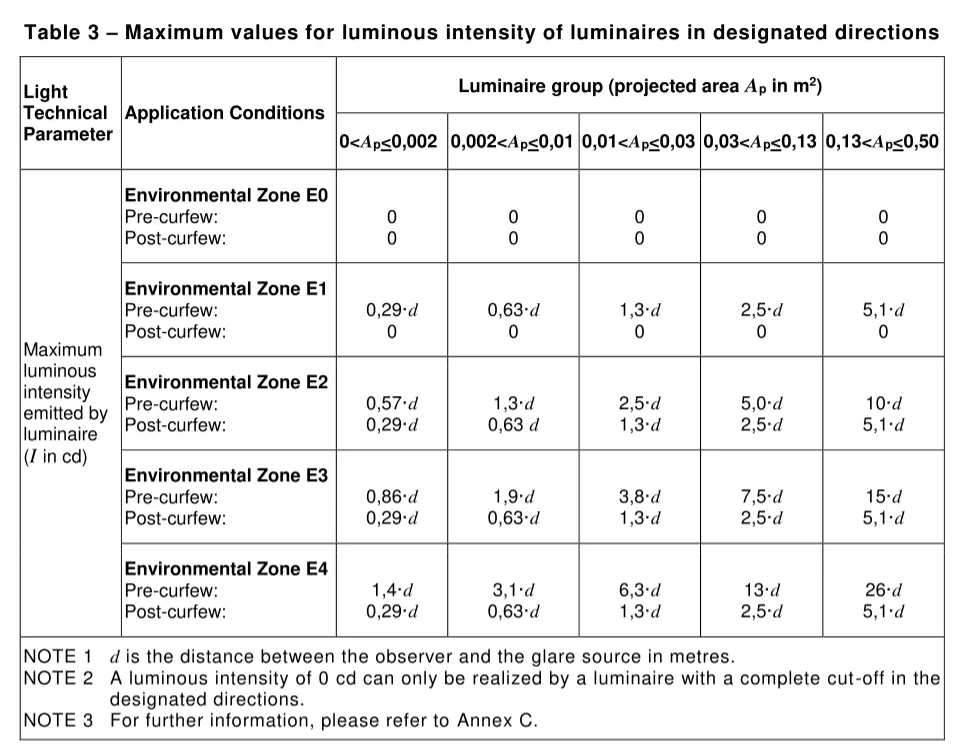

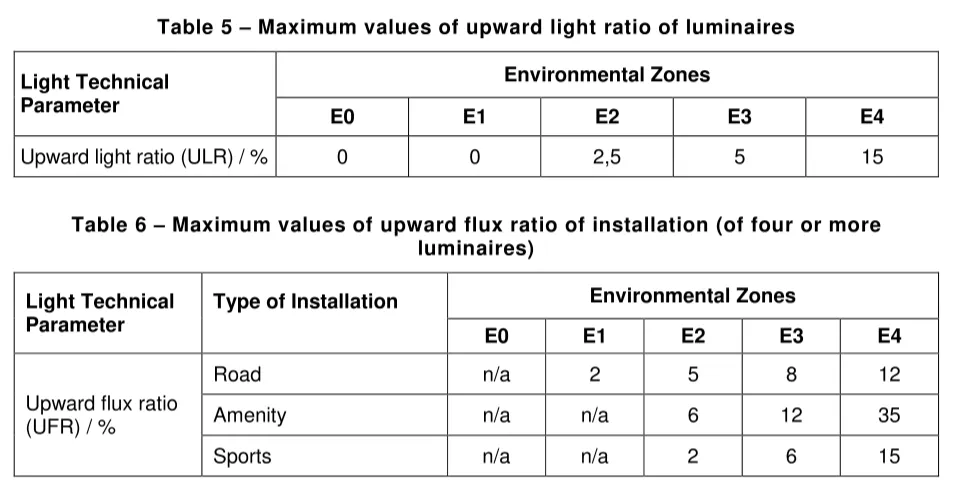

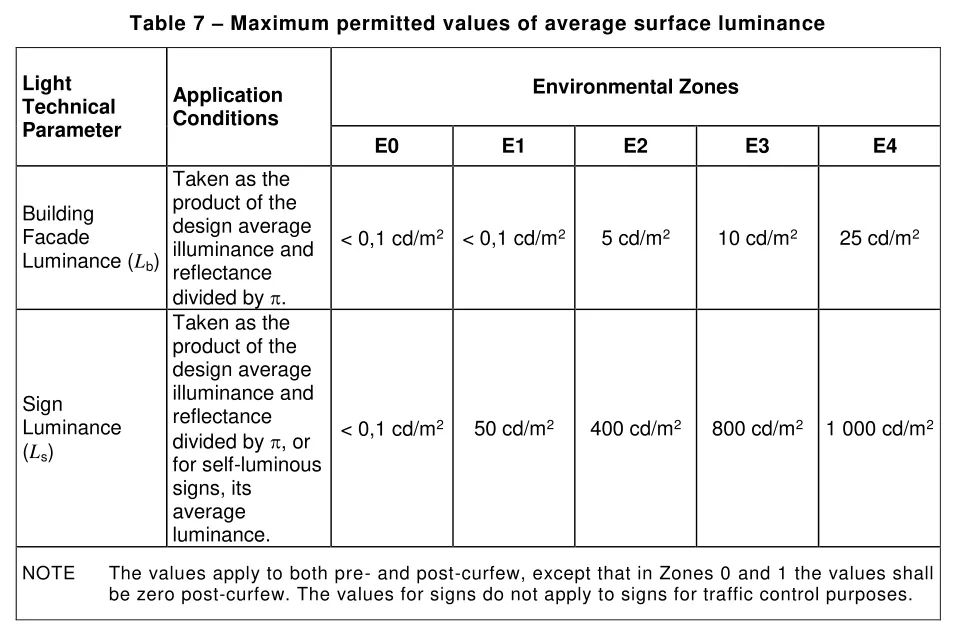

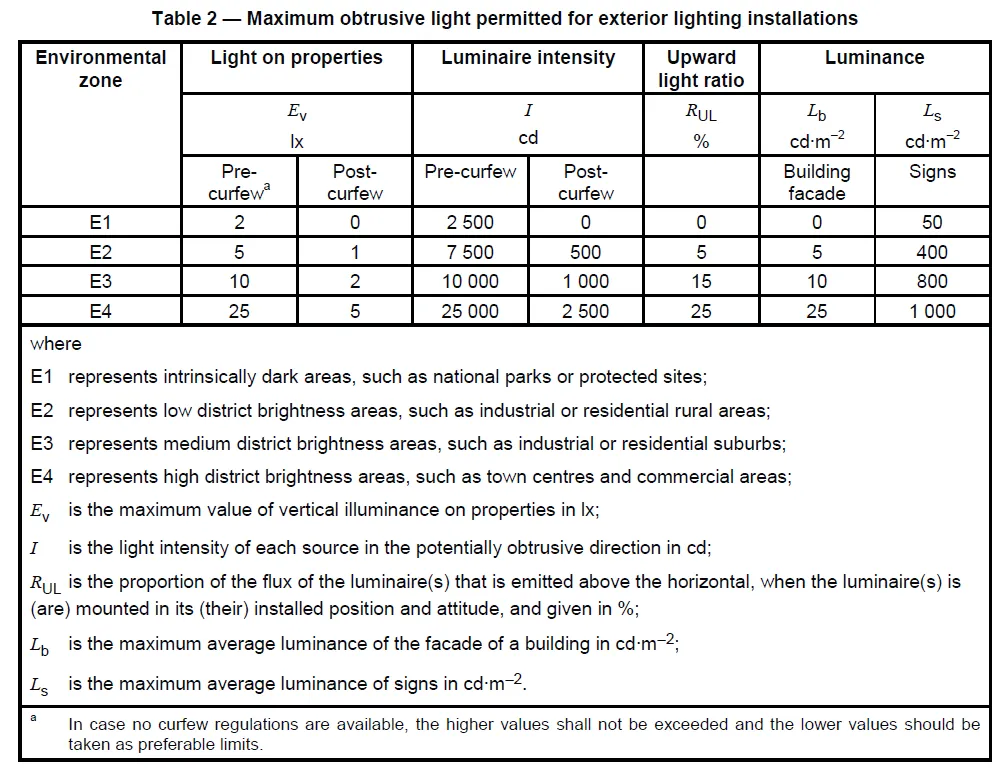

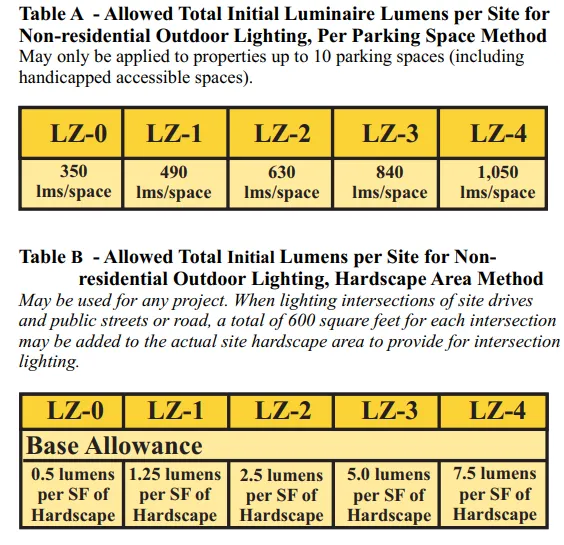

为了控制光污染,各大国际标准如CIE 150:2017、EN 12464-2:2014、IES MLO 2011和TM15-07,提出了明确的控制要求和计算方法。国内也颁发了参照CIE标准的本地化标准GB/T 35626-2017:室外干扰光限制规范,主要参照CIE 150:2017。以上标准基本可以分为两大阵营,CIE/EN标准和IES标准。在CIE/EN的标准中,基本都是将户外环境分成了4-5个区域,并按分区提出了控制参数限值。

↑CIE标准中的分区和垂直照度限值↑CIE标准中的分区光强限值

↑CIE标准中的上射光通比要求

↑CIE标准中的亮度限值

↑EN标准中的控制参数限值,与CIE标准略有差异,主要是标准发布时间差问题导致的。

↑我国标准,基本参照CIE,差异部分为标准发布时间差导致

在刚刚发布的DIALux evo 13版本中,也加入了针对户外光污染的计算。

干扰光数值的计算

用户现在在 DIALux evo 13 版本中可以计算几个重要的干扰光参数,包括:

I (光强)

ks(眩光指数)

Ruf(上射光通量比)、Rul(上射光通比)

RULO(上射光输出比)、RDLO(下射光输出比)

这些新指标让设计师对其设计如何影响周围环境拥有更好的控制和可视性。

在新版本中可以查看这些计算结果并检查是否符合相关标准,我们在首步开发中考虑了以下标准:

CIE150:2017

EN 12464-2:2014

LAI:2012

ÖNORM O 1052:2022

RG 数值计算选项

我们为计算 RG 值(光幕照明的眩光等级)添加了两个选项:

1. 固定值,便于比较。

2. 可以放置在场景中的特殊光幕照明表面,用于模拟更复杂的环境。

此功能允许用户根据项目需求来定制 RG 计算。

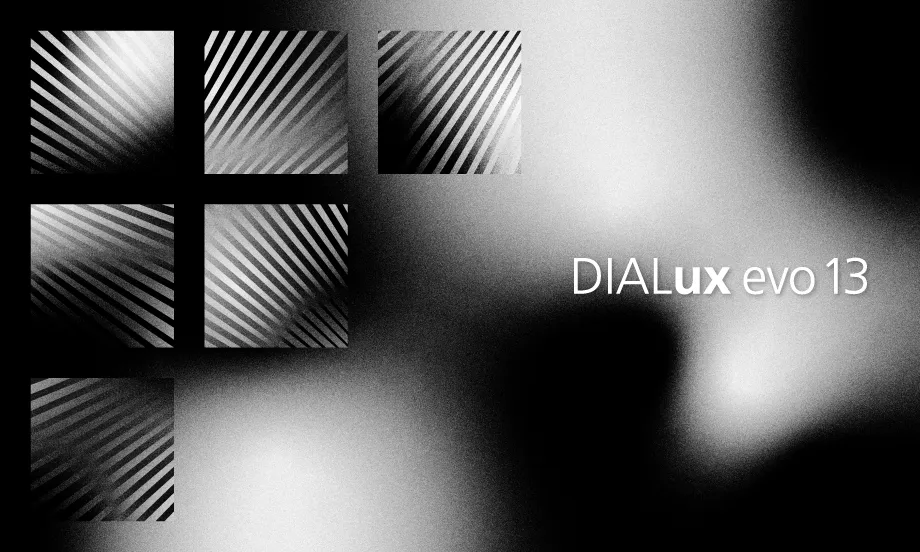

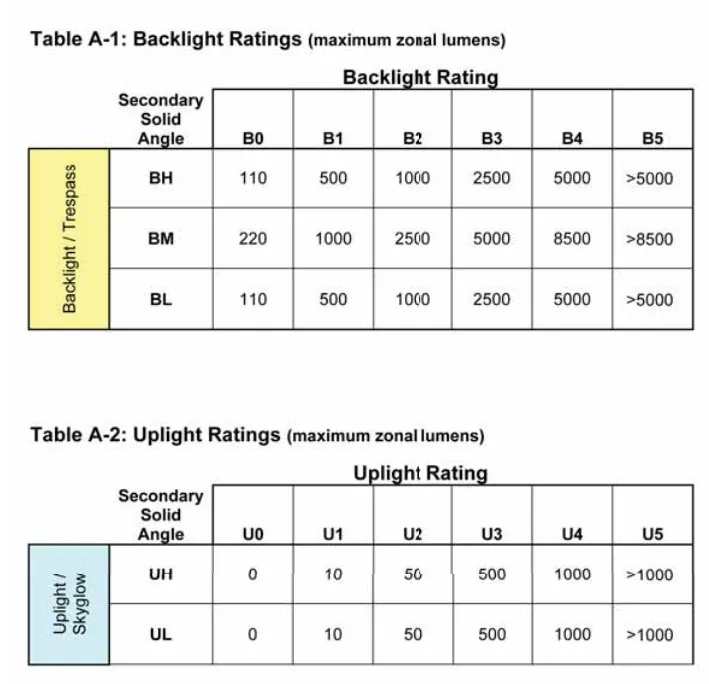

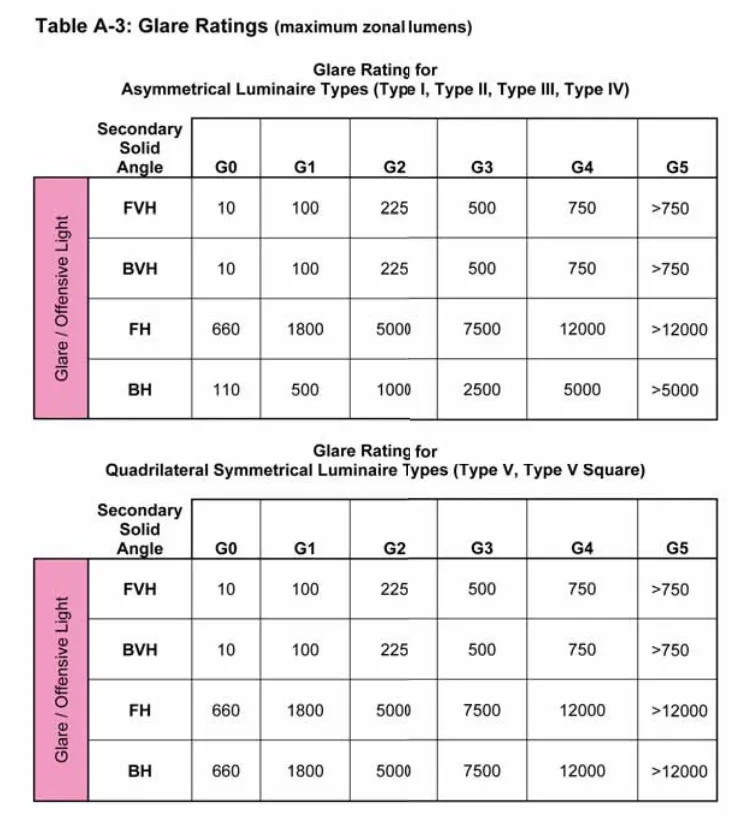

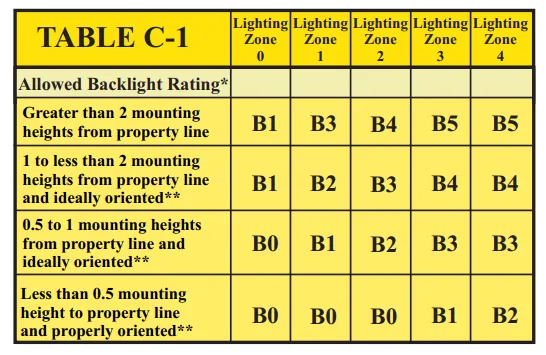

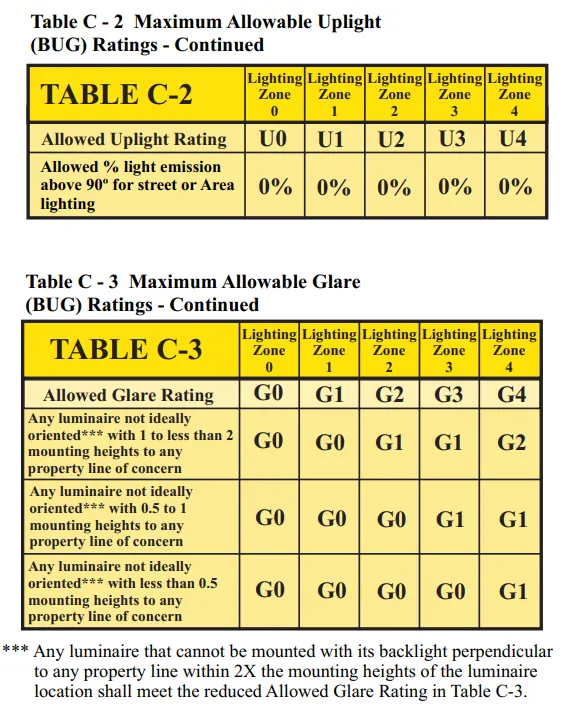

而IES标准,则使用了完全不一样的参数指标。

在IES MLO 2011和TM15-07中,户外环境分区与CIE类似,但采用BUG评级。

LZ0:自然保护区

要求严格控制任何形式的向上光和溢散光,几乎不允许任何夜间照明,向上光的允许输出比(UR)应接近0%。

LZ1:乡村或低亮度区域

适用于生态保护区或居住区,要求较低的眩光和溢散光控制,向上光的输出不应超过1%,后光应严格限制在邻近区域内。

LZ2:郊区或中等亮度区域

适用于一般城市的住宅区,要求中等程度的光污染控制。向上光输出比应低于2%,溢散光应限制在邻近环境亮度的2-3倍以内。

LZ3:城市商业区

允许较高的照明水平,但仍要求限制向上光和溢散光。向上光输出比应不超过3%,GR值(眩光指数)应保持在合理范围内。

LZ4:高亮度城市中心或交通密集区

允许的光污染限制较为宽松,但仍要求遵循合理的眩光控制和溢散光管理。向上光不应超过5%,以避免对天空亮度的严重影响。

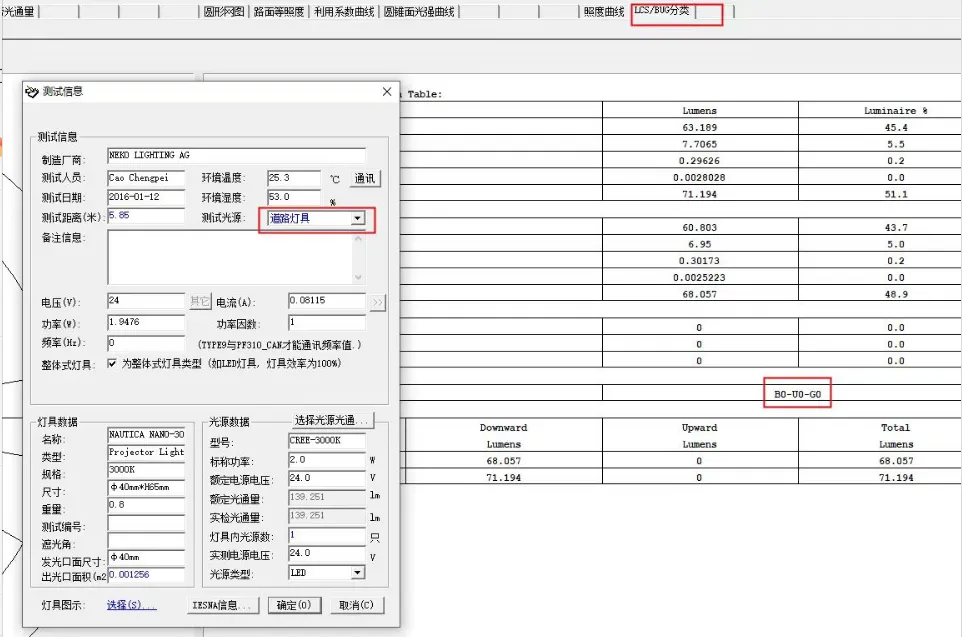

BUG评级

B(Backlight):计算灯具在背光区(90-180度)方向上的光输出,避免灯光影响周围环境。

U(Uplight):计算灯具向上光输出的比例,应严格控制UR值,通常要求UR ≤ 1%。

G(Glare):计算眩光控制,通过GR或UGR值进行量化评估,确保眩光控制在可接受的限值内

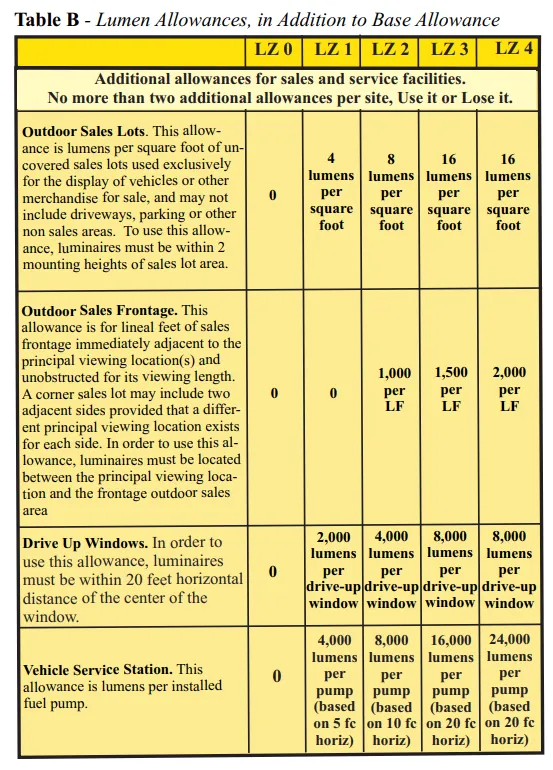

对于不同的区域,通常会限制不同的BUG,例如。

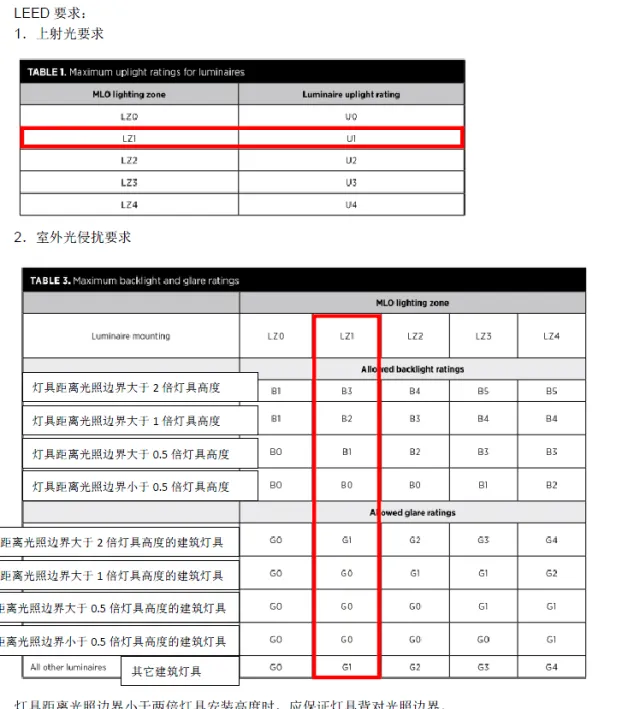

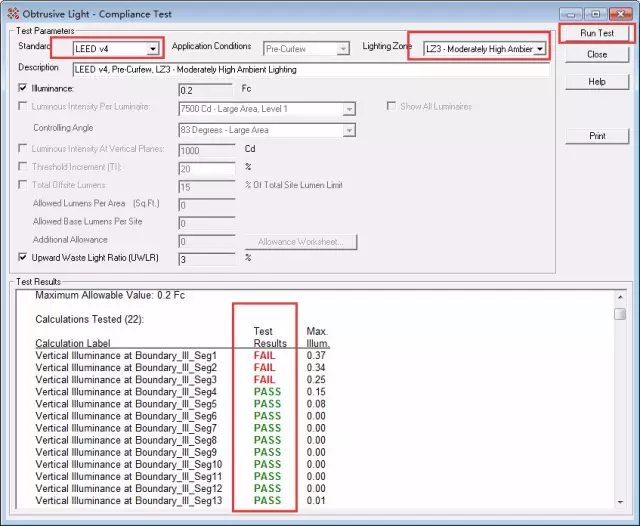

在LEED标准,也采用类似的限值。

当然,IES标准里也会同CIE一样,限制照度亮度等参数。

对于IES标准中的这些参数的获取,BUG评级可以通过配光报告获取,也可以通过其他光度软件获取。

↑配光测试软件里选择道路灯具即可导出BUG

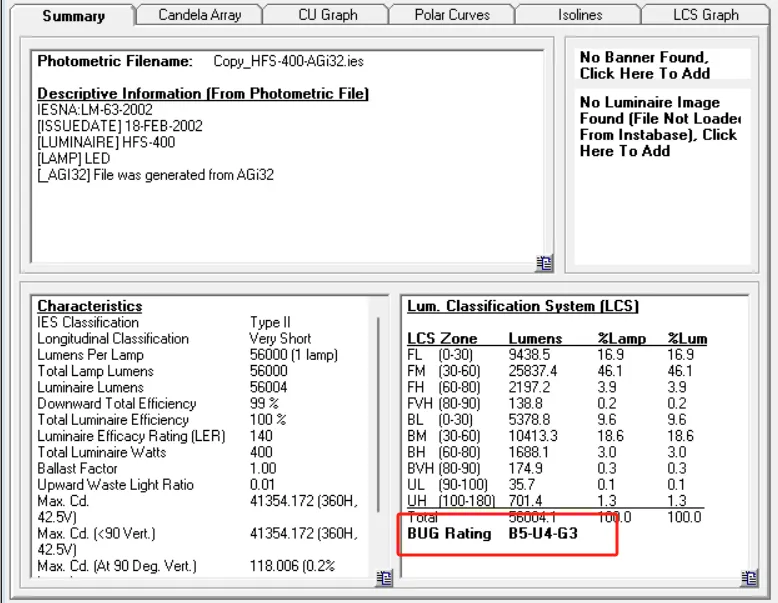

↑Photometrie Tollbox软件中的BUG参数其他的照度亮度眩光限值,则可以使用AGi32进行计算。

↑AGi32中对于光污染干扰光的计算,可以选择IES或CIE或LEED标准,比DIALux完善一些。

以上就是对于户外光污染的解读和计算